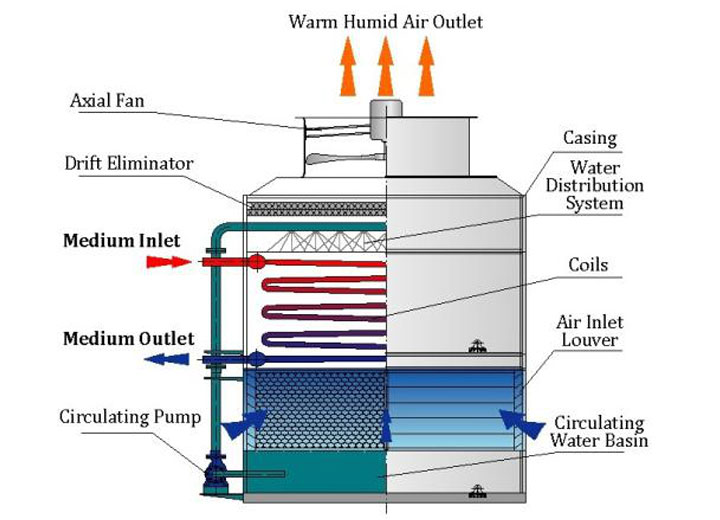

Evaporative cooler (condenser) is a kind of high efficiency energy-saving equipment developed by Longhua Technology on the basis of absorbing advanced technology at home and abroad. Compared with similar products, it's more energy saving, water saving, simple packless structure makes the air inlet more unobstructed, less resistance, suitable for use in bad environment. Evaporative cooler (condenser) can be widely used in petrochemical industry, light industry medicine, refrigeration and air conditioning, food refrigeration and many other industries.