-

High Heat Exchange Efficiency

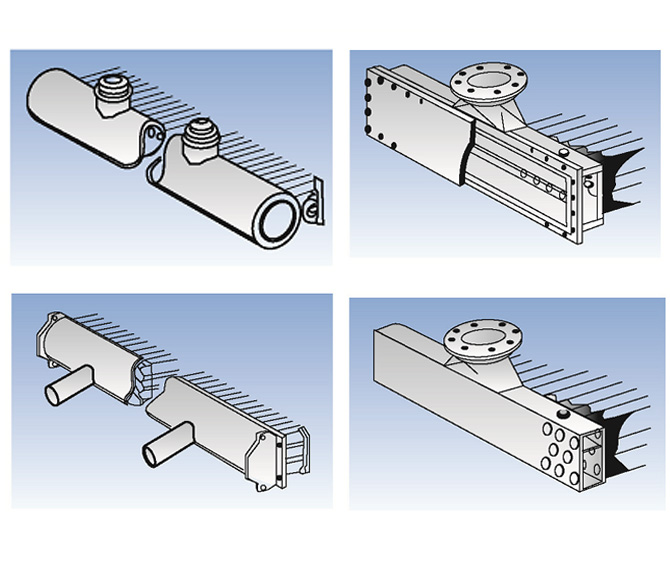

Both latent heat of evaporation and sensible heat of air cooling are used for cooling. Moreover, the condensing coil adopts the form of multi-row coils, which can increase the flow, increase the heat exchange area and achieve better heat exchange effect.

-

Less Investment

As evaporative cooler integrates heat exchanger, circulating cooling tower and circulating water pump as a whole, which save the equipment of the purchase and construction of special cooling tower, circulating water pump, pump room, circulating water pipe, charging device,heat exchanger and so on, as well as the cost of civil construction and installation. Save about 40-60% of investment.

-

Save Water

The cooling effect of the evaporative condenser is to use the latent heat of water evaporation and consume less water.Low resistance and high efficiency eliminator is adopted to avoid the loss of cooling water mist.Evaporation loss and sewage in the water cycle account for about 3-5% of the total water, if the water quality is better, the water loss will be less than 2%.

-

Energy Conservation And Environmental Protection

The cooler is its own independent circulation cooling system, not affected by other equipment, the circulating water quality is easy to ensure, which is conducive to equipment maintenance and environmental protection standards, it is a new energy-saving and environmental protection

-

Compared With Air Cooler

Evaporative condenser (cooler) has lower energy consumption, less investment, and is less affected by natural weather conditions. Moreover, the equipment is more compact, small in size, and more convenient for installation and transportation.