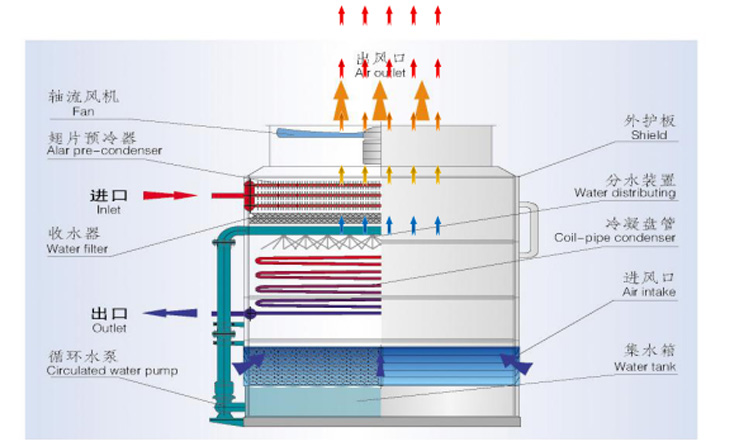

Efficient compound cooler combine three-stage series cooling system of "air cooler water cooler cooling tower" is combined in an intensive equipment, but compared with the traditional series cooling system, it has a significant "triple three different".

1. Evenly covered by the water film, do not have dry points, prevent scaling and corrosion under the scale; most liquid water will be intercepted by the water collector in the upper part of the spray device, the saturated water vapor will be intercepted twice when passing through the outside of the fin tube bundle, the saturated water vapor will become unsaturated steam to the outside of the wind tube when passing through the overheated section of the fin, can not see the phenomenon of white fog, and the air heat transfer coefficient of the outside of the humidified fin has also been improved. After a series of cascade utilization, the water has also been reused three times to achieve "eat dry press clean ".

2. "Three differences" that the equipment and the traditional air cooler, water cooler, cool water tower has a great difference. The fin section of the equipment is different from that of the air cooler, because the traditional air cooler is usually operated in dry air environment, aluminum fin outside basically does not need anti-corrosion, but the compound cold fin outside is operated in wet air environment, so the fin tube bundle needs to do the whole anti-corrosion, generally take the steel tube sheet after processing the whole hot dip zinc anti-corrosion; this equipment evaporates the light tube section and the water cooler light tube bundle also has the very big difference, the water cooler cold medium generally goes through the tube side, the shell side goes through the heat medium, but the complex tube side goes through the heat medium. The composite cooling tower is usually packed, but the composite cooling tower is not packed in the counter current contact section of wind and water, and the composite cooling tower is generally installed on the ground, and the composite cooling is movable equipment, which can be easily installed on the pipe gallery, platform or roof.