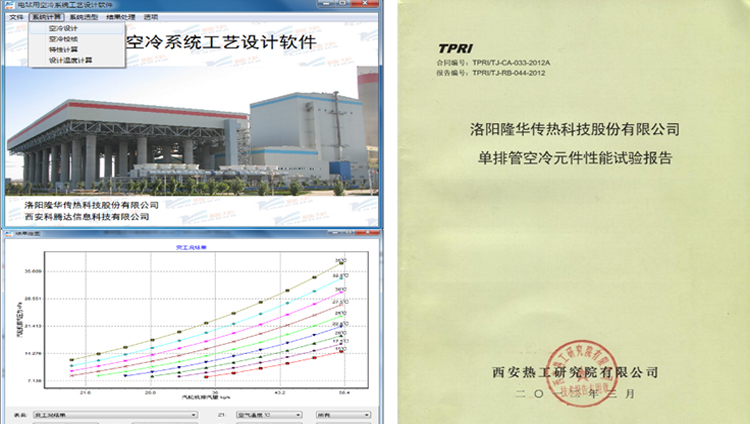

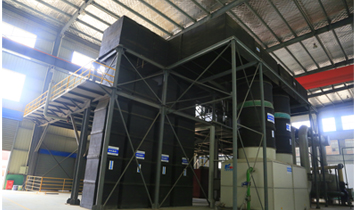

The establishment of testing and Testing Center

fills the gap in the field of refrigeration and heat transfer in China.

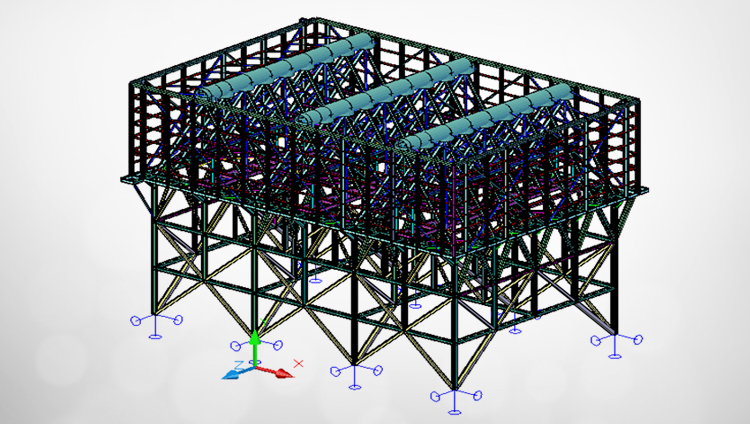

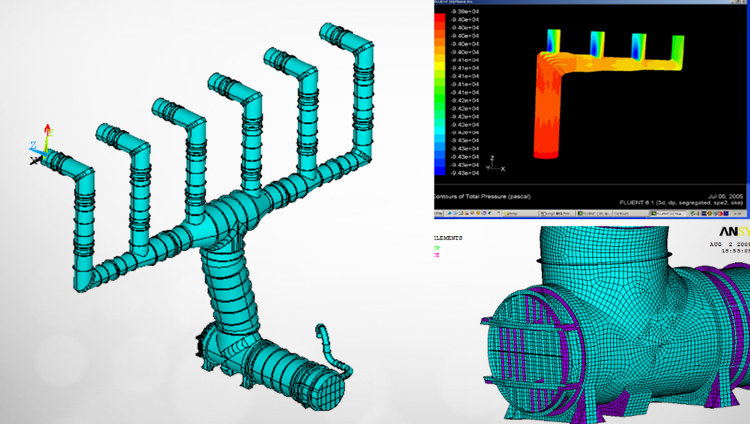

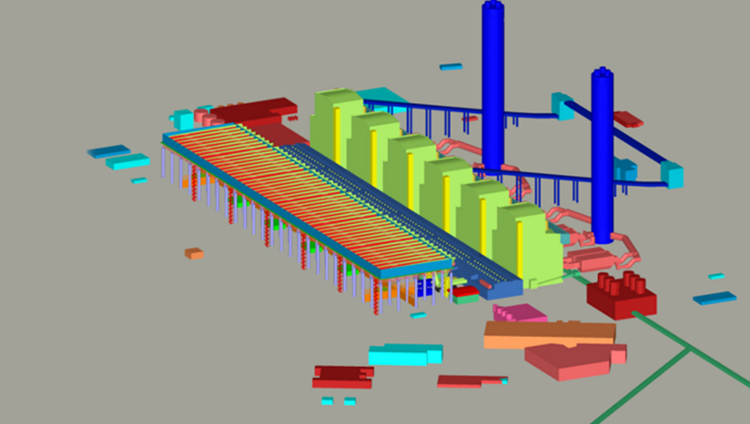

Full-performance testing station simulate the main operation conditions of the power station to test

the system performance of direct air-cooled condenser plus evaporative peak cooling device,

including heat exchange performance, system reliability, stability, economy, especially the ability

of full load operation in summer and the reliability of Antifreeze Operation in winter.